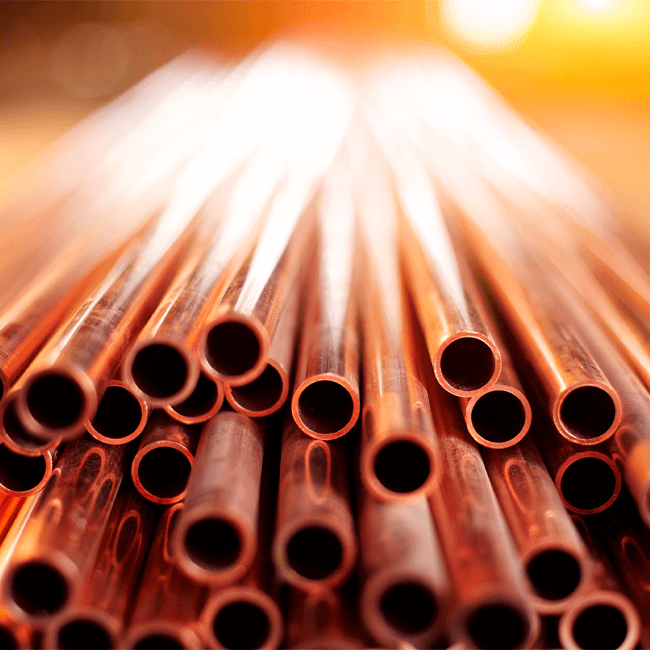

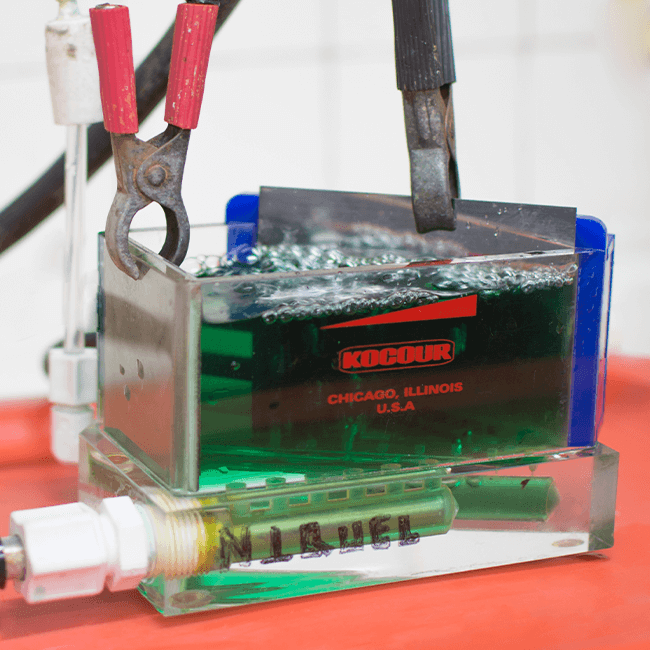

Copper processes have the function of covering a metal or plastic piece with a thin layer of copper, these copper deposition processes, in addition to having decorative purposes, are normally implemented for their functional properties in the piece, such as the increase in conductivity and its ability to provide surface leveling. Copper processes are mainly used as a base for a subsequent application of nickel, tin or chromium, in order to increase its durability and protection.

We offer additives for Copper processes:

- Acid Copper

- Alkaline Cyanide Copper